The purchasing price is not the important factor in selecting the right components of a pumping station. Only the total cost of ownership matters, including the power supply energy costs. TMVW - the East Flanders water company - has selected components with the highest efficiency for the new station in Buggenhout - therefore also VLT® drives.

The purchasing price is not the important factor in selecting the right components of a pumping station. Only the total cost of ownership matters, including the power supply energy costs. TMVW - the East Flanders water company - has selected components with the highest efficiency for the new station in Buggenhout - therefore also VLT® drives.

— TUESDAY, 02 SEPTEMBER 2014 BY DANFOSS POWER ELECTRONICS A/S

The Danfoss VLT® AQUA Drive offers the highest available efficiency: 98%. It is equipped with DC coils in the intermediate circuit to lower the harmonic disturbances while offering the highest efficiency. The ratio between the input current at 50Hz and the RMS input current is higher than 0,93. This low level of harmonic disturbance contributes to lower the heat losses in the grid and in the supply transformer.

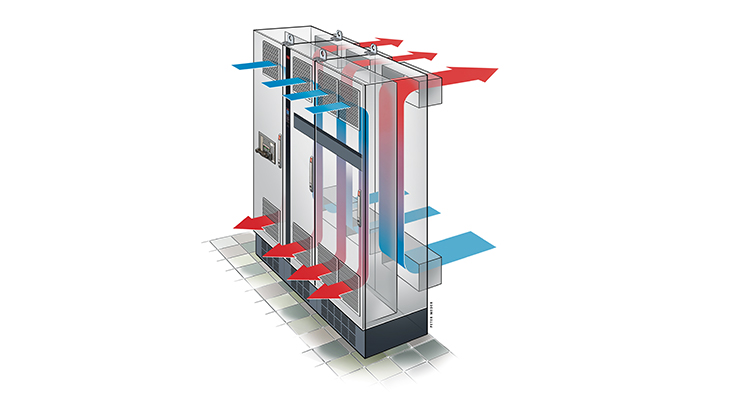

80% of the heat losses in the drive are deviated by the ventilator of the drive directly outside the building through wall openings. The remaining 20% of heat generated by the drive - and the heat generated by the other components like the transformer - is evacuated by variable speed controlled fans according to a temperature measurement. This also saves energy.

Since the heat is dissipated into the open, the room ventilation can be dimensioned smaller and less energy consuming.

Only the superior level of the building is apparent above the ground surface with the part containing the electrical rooms and the access to the underground pumping room.

The back channel cooling system of the VLT® drive.

The back channel cooling system of the VLT® drive.

There is a low level of noise generation outside the building because of noise absorbing exhaust ducts.

There is a low level of noise generation outside the building because of noise absorbing exhaust ducts.

The 3 x 500 kW VLT® AQUA Drives standing side by side. The room is just wide enough to contain all three.

The 3 x 500 kW VLT® AQUA Drives standing side by side. The room is just wide enough to contain all three.

TMVW is a public company in charge of the distribution of drinking water for about 80 municipalities and cities covering the majority of the province of East Flanders (Belgium) and the surroundings.

In 2008, TMVW has distributed 84 mill m³ of water to more than 433.000 customers and is maintaining 10.584 km of piping. In 2009, TMVW has installed a transportation pipe between the cities of Buggenhout and Opwijk. Only 11% of the water production is coming from own resources. The remaining drinking water is supplied by other public water companies.

3 major pumping sitesTMVW owns 3 major pumping sites in Brakel, Buggenhout and Ursel. The one situated in Buggenhout constituted of two stations is relying on the delivery of water from AWW, another public water company. The first station inaugurated in 1970 can no longer meet the constantly growing demand seen in recent years and it was decided to double the capacity.

Energy efficiency requiredTMVW carefully required components delivering the best efficiency in their tender description.