The VLT® DriveMotor FCM 106 is delivered factory mounted to either an IE4-rated permanent magnet (PM) motor or IE2-rated induction motor (IM). Alternatively, for full flexibility in motor choice, system design and energy efficiency, choose your own motor and attach the standalone VLT® DriveMotor FCP 106.

Installation costs and system complexity are significantly reduced thanks to the compact design of the VLT DriveMotor FCM 106. Costs are further reduced as the need for cabinets and long motor cables are eliminated. Installation is simple due to the integrated cooling system and an individually adjustable motor adapter plate.

The standalone VLT DriveMotor FCP 106 provides you with a high level of flexibility and stable, energy-efficient operation as the drive automatically sets the optimal parameters for the attached motor.

3 x 380-480 V...0.55-7.5 kW

Drive lifetime is extended and harmonic load on the mains is minimized thanks to the built-in DC choke which reduces THDi to less than 46%

Connectivity is flexible thanks to the integrated FC Protocol, Modbus, Metasys and BACnet or optional Profibus

The drive operates reliably in wet, dirty and corrosive environments due to the IP66/Type 4X Outdoor enclosure and PCB protection

Time is saved as the motor data is pre-programmed and parameter sets can be easily transferred using a memory module

Energy is saved and drive lifetime is extended due to the sleep mode

Pumps, fans and conveyors.

The integration of a servomotor and electronic drive unit in the same housing reduces costs, improves flexibility and makes this drive system ideal for applications that require high flexibility and dynamics such as those in the food and beverage and packaging industries.

The decentralization of the drive unit offers benefits in mounting, installation and operation. And, depending on the application, up to 60 drives can be integrated into the servo drive system.

3 x 380-480 V...3.0 kW

Rated voltage: DC 300 V

Rated torque: 1.7 – 2.1 Nm

Installation is fast and costs are reduced due to DC supply to drives from a central power supply module and the use of hybrid cables

Enhanced diagnostics and reduced downtime are possible as all components support the controller area network (CAN) bus

Operating status can be easily monitored thanks to LEDs on the front of the unit

Various kinds of applications in the packaging and food and beverage industries.

Designed for simplicity and robustness, the VLT® Decentral Drive FCD 300 is a user-friendly product with high performance and a strong protection degree.

A decentral drive solution eliminates the need for space-consuming control cabinets. And, with the drives placed near the motor, there is no need for long-screened motor cables.

The very robust enclosure and special surface treatment ensure the VLT Decentral Drive FCD 300 can withstand harsh environments and cleaning agents used in wash-down areas. And its smooth surface is easy to clean.

3 x 380-480 V...0.37-3.3 kW

Installation is flexible as the drive adapts to any brand of motor

Servicing is fast and easy due to the pluggable twin-part design

Cleaning is easy thanks to the drive’s smooth surface

Cable savings are possible as a result of the integrated power and fieldbus looping terminals

Commissioning is easy as set up is handled through a remote control panel or fieldbus communication

Local disconnection is possible due to the integrated lockable service switch

With its IP 66 enclosure, the VLT Decentral Drive FCD 300 is ideal for conveyor applications, sorter systems, installations in wash-down areas or widely distributed applications with a large number of drives in, for example, the food and beverage and materials-handling industries.

The VLT®Integrated Servo Drive ISD® 510 is a high-performance decentral servo motion solution that comprises a central power supply VLT® Servo Access Box (SAB®), drive modules and cabling infrastructure. The motion control is integrated into the drive so that motion sequence can take place independently. This releases the central PLC and offers a highly flexible drive concept.

The decentralization of the drive unit offers benefits in mounting, installation and operation. And, depending on the application, the SAB can power up to 64 drives in a servo drive system.

400-480 V...0.72-0.94 kW

3 x 400-480 V...7.5 kW

Rated voltage: DC 600 V

Rated torque: 1.7-3.4 Nm

Easy and fast installation due to hybrid cables in a daisy-chain concept and DC supply to the drives from the central SAB

Fast process communication as the open system supports both EtherCAT® and POWERLINK®

Selection of the most suitable drive for the application’s torque and power requirements due to 192 motor variants

Direct connection to the servo drives for fast commissioning, diagnosis and service with the removable Local Control Panel (LCP)

Wide range of additional options to meet system and application-specific requirements

Packaging, food and beverage and pharmaceutical machinery applications.

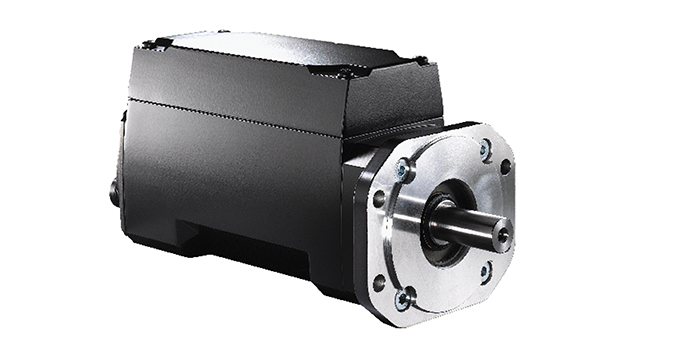

The VLT®DriveMotor FCM 300 is an integrated drive-motor solution which combines a VLT frequency converter and a high-standard-quality motor in a single product.

The drive is attached in place of the motor terminal box. It is no higher than the standard terminal box and no wider or longer than the motor. Incorporated to a high-standard-quality motor, the drive is available in many variants that can be individualized to suit customer requirements. Electromagnetic interference is eliminated as motor cables are unnecessary. And heat from the drive is dissipated together with the motor heat.

3 x 380-480 V...0.55-7.5 kW

The drive withstands harsh environments thanks to the robust enclosure

Commissioning time is reduced as the motor and drive are perfectly matched to each other

Total motor-inverter protection is guaranteed due to thermal protection

Space is saved as the DriveMotor is installed on the machine and no panels are required

Commissioning is easy due to set up which is controlled through a remote control panel or fieldbus communication

Pumps, fans, compressors and conveyors.

Designed for simplicity and robustness, the VLT® Decentral Drive FCD 302 is a user-friendly product with high performance and a strong protection degree.

A decentral-drive solution eliminates the need for space-consuming control cabinets. And, with the drives placed near the motor, there is no need for long-screened motor cables.

With the VLT Decentral Drive FCD 302, all the options are built into the unit reducing the number of boxes to be mounted, and the connections and terminations in the installation. As a result, labor costs and the risks of failure are dramatically reduced.

3 x 380-480 V...0.37-3 kW

Installation is flexible as the drive adapts to any brand of motor

Servicing is fast and easy due to the pluggable twin-part design

Cleaning is easy thanks to the drive’s smooth surface

Cable savings are possible as a result of the integrated power and fieldbus looping terminals

Direct connection to a PC is possible thanks to the integrated USB port

The need for PLC capacity is reduced due to the built-in smart logic controller

With its IP 66 enclosure, the VLT Decentral Drive FCD 302 is ideal for conveyor applications, sorter systems, installations in wash-down areas or widely distributed applications with a large number of drives in, for example, the food and beverage and materials-handling industries.

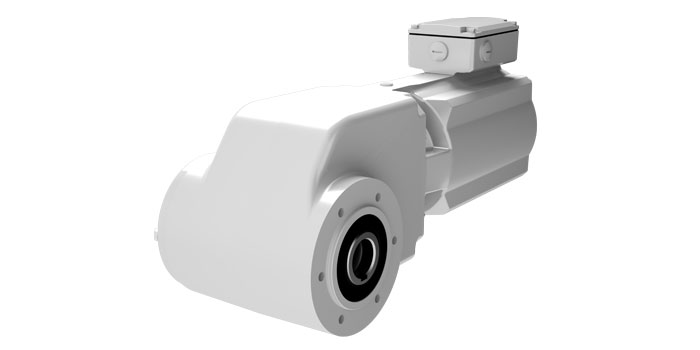

The VLT® OneGearDrive® is a highly efficient, permanent magnet, three-phase synchronous motor coupled with an optimized bevel gear box which helps to optimize plant productivity and reduce energy costs.

With only one motor type and three available gear ratios, the motor concept covers all typical versions of conveyor drives commonly used in the food and beverage industry. The reduced range of physical configurations reduces costs and simplifies spare-part storage. Uniform mechanical dimensions reduce engineering and installation time and costs.

The drive comes in two versions: Standard for use in dry and wet production areas and Hygienic for use in wet areas and environments with high cleaning intensity including aseptic and cleanroom production areas.

Up to 40% energy savings compared to conventional systems thanks to high system efficiency

Less noise and no airborne germs and dirt particles drawn into motor and expelled back into the surrounding air due to fan-free operation

Unrestricted use and high protection in wash-down areas thanks to high degrees of protection

Easy to clean due to smooth enclosure design

Fast, reliable connection and lower installation costs as a result of motor and brake connections via terminal box with CageClamp® technology

Resistance to detergents and disinfectants thanks to aseptic coating

Conveyors.