Efficiency increases and energy savings go hand in hand at Jindal Polyfilms in India. In 2009 the company installed Danfoss VLT® HVAC drives to control the chillers that ensure the correct water temperature throughout the production process.

Efficiency increases and energy savings go hand in hand at Jindal Polyfilms in India. In 2009 the company installed Danfoss VLT® HVAC drives to control the chillers that ensure the correct water temperature throughout the production process.

— WEDNESDAY, 25 NOVEMBER 2015 BY DANFOSS DRIVES

Jindal Poly Films Limited is India’s largest supplier of polyester (PET) and polypropolene films with a total production capacity of more than 400,000 tons per year across its production sites. In 2009 the company embarked on a technology upgrade of its PET lines in its production facility near Nashik, about 200 km from Mumbai. The goal was to increase productivity while minimizing energy consumption.

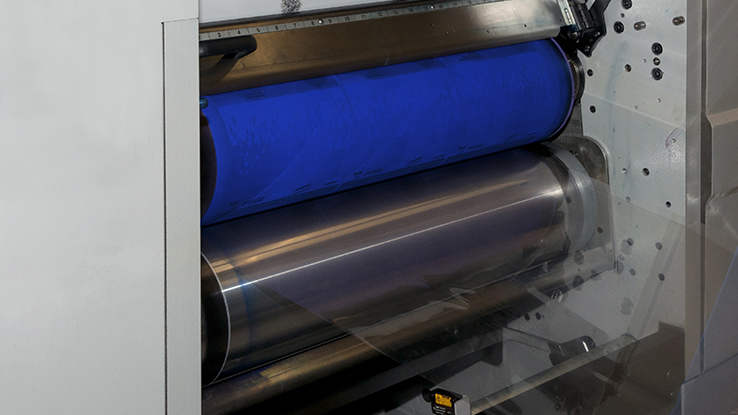

“The quality of our products is very much influenced by the temperature of the films during production. We decided to install new centrifugal chillers to maintain the required water temperature for the chill and cooling rolls, the dehumidifier section of the production lines and also the chilled water supply for the metalliser machine,” says Mr. Shailesh Parmar, deputy general manager for plant maintenance at Jindal Polyfilms.

System overviewEach of the new chillers has a 450 TR capacity with compressor controlled by a VLT® HVAC Drive FC 102. The drive is kept safe in the extremely dusty environment by an IP54 enclosure. Danfoss’ efficient back channel cooling concept has been employed as part of the drive’s heat management system.

“Back channel cooling directs 85% of the heat generated by the drive outside the panel or switch room where it is installed. Not only does this ensure reliable operation, it also reduces the need to install additional air conditioning, thereby reducing both initial and running costs,” explains head applications specialist at Danfoss India, Ganesh Iyer, who was in close contact with both the customer and chiller manufacturer during the project.

The frequency converter operates in the speed range of 70-100% of the base speed of 2950 rpm. In this phase the inlet guide vane is fully opened to enable capacity control through the drive.

Typically, the drive operates at 357 A, well below its rated capacity of 600 A, for the greater part of the refrigeration cycle. Since the compressor runs at the minimum rated speed (70% of base speed) during low load conditions, the drive helps to prevent frequent starts and stops, avoiding unnecessary wear of the system.

A closed loop controller is implemented in the chiller module to control the chilled water outlet temperature and drive speed, and a separate controller module controls the operation of the chillers.

In the event that process temperature is not maintained with one chiller running at 100%, the controller brings the second chiller into operation. Capacity control is then achieved by running the first chiller at full capacity and modulating the compressor speed of the other to achieve the desired temperature.

Higher quality with less energyThree years into operation the drive controlled chiller system continues to perform to the expectations of Jindal Polyfilms. Mr. Parmar is satisfied with the results.

“The new chillers have made a difference in the quality of the film we produce, due to the fact that we can control the temperature of the chilled water precisely. Compared to a similar system without drive control, our chillers use 25-30% less energy, so in addition to better quality, we are also reducing our energy demand.“

Application highlights:Compressor control in industrial chiller

VLT HVAC Drive FC 102

315 kW, IP 54 enclosure

Back channel cooling

Jindal Poly Films Limited has been in the polyester business since 1984, and is India’s largest producer of polyester (PET) and polypropylene (OPP) films. In 2003 Jindal Polyfilms entered the metallizing business and currently has India’s largest metallizing capacity.