The commercial refrigeration sector includes food retail establishments such as supermarkets, hypermarkets and convenience stores. It also includes precision air conditioning in data centers.

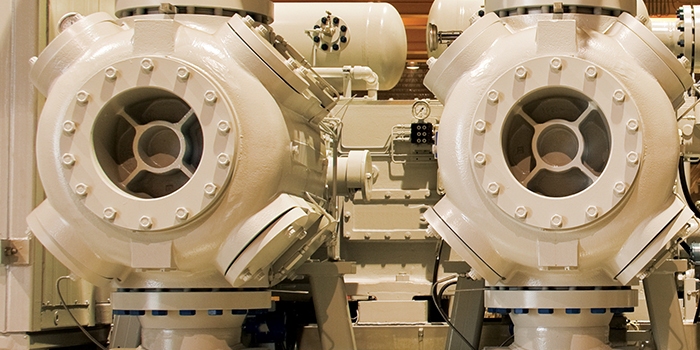

Typical applications include racks and packs, condensers, evaporators and pumps.

Reliability and thermodynamic efficiency are the key factors in any commercial refrigeration system efficiency and effectiveness. A range of functionalities tailored to refrigeration applications ensures versatile compatibility, stable performance, system reliability and optimal energy efficiency.

The industrial refrigeration sector includes cold stores and cold rooms, meat, seafood and other food and beverage processing units, bio-pharmaceutical, chemical and textile plants. Typical applications include process chillers, condensers and evaporators/air-handling units and pumps.

For fresh fruit and vegetables, the initial cooling, processing and cold storage are amongst the most energy-intensive processes in the food industry. Significant volumes of refrigerants and high heat levels are needed to slow down spoilage and maintain pre-harvest freshness and the flavor of fruit and vegetables. Danfoss AC drives provide fast cooling and freezing when necessary. They also maintain uniform temperature, humidity, air circulation and fresh air supply for cold storage maintaining food in marketable condition for a period of months and consuming less electricity than conventional installations.

There are many different modes of refrigerated transportation such as reefers, containers, trucks, trailers, trains, buses and ships. AC drives are used to control the applications that ensure goods remain in the best possible condition. They tailor output to demand to optimize energy usage and reduce component wear to ensure the lowest cost of ownership.

A range of refrigeration-dedicated features ensures reductions in costs and energy consumption. For example, during night-time and winter weather conditions when ambient temperatures are lower, the VLT® Refrigeration Drive automatically switches compressors and fans into ‘sleep mode’. The optimum temperature is maintained taking the outdoor temperature into consideration. The drive detects any increase in ambient temperature and reacts by restarting the applications. Controlled refrigeration uses significantly less power which helps to reduce the transportation fuel bill and the level of exhaust emissions. Reliability is vital during the transportation of perishables. Danfoss AC drives ensure that compressors and fans keep operating even during minor power shortages.

Standalone as well as OEM-specific customized drives significantly improve refrigeration system reliability and COP, and lower total cost of ownership.

Temperature-controlled logistics are important to ensure the preservation and safe transfer of food, beverages and medicine to consumers from the harvesting or production stages. Typical applications include racks, packs, process chillers, condensers and evaporators/air-handling units and pumps. The reliability and thermodynamic efficiency of Danfoss AC drives ensure a hygienic and controlled environment in your cold stores, food processing plants, food retail outlets and throughout the entire cold chain.